Audi TT Build Thread

#1

Goals:

450wHP on 94 octane @ <=28PSI; no N2O

22PSI by 3500RPM

11.xx 1/4 mile

>30MPG

Daily driver that can kick the crap outta SK Winters (AWD + Studded Winters + balanced chassis = love)

Engine:

2.0L displacement, 10:1 compression

Bored to 82.5mm – Wossner pistons (I wanted 83mm, but it would have been a 6-week wait for pistons!)

Stroked to 92.8mm - AEG crank

AEB head – Supertech Inconel valves

ARP Main, rod, and head fasteners

Calico coated ACL race bearings - rods and mains

GT3071R turbo, .63 AR

Treadstone TR8 with custom aluminum piping

3” Stainless turbo-back

Eurodyne Maestro

Wide-band O2 conversion

Water/meth injection

Lucas 830cc injectors, Walbro inline pump

Suspension/Chassis:

H&R SS-adustable coilovers

19mm rear anti-sway

Adjustable rear control arms

Defcon bushings, spherical bearings, poly bushings/mounts

~225lbs weight reduction

Wheels/Tires/Brakes:

17” OZ Ultraleggera

Bridgestone RE-01R

Wilwood Superlite Calipers

330mm two-piece, aluminum-hat rotors

ATE Super Blue

This car is my daily driver so I'm basing the build around drivability. The engine/suspension/brakes can easily handle another 100+wHP with just a different turbo (GT35+), but I'm trying to keep it moderate. Spool and power-band are very important to me, hence my choice of a turbo that some would find to be under-sized considering the build. I'm leaving a couple of mods on the table – cams and an SEM intake manifold – just to give me something to quell inevitable future mod-itis. I should have no problem with 400wHP as-is, then the cams and manifold will easily pull another 50+wHP, but my turbo will be maxed out at that point. Depending on how I feel about the drivability, I might go to a GT3076R and push for 500wHP. My only regret is that I didn't do the extra work and go to 2.2L of displacement; although, doing so does put the rod ratio and angles at fairly undesirable levels for a daily driver, so it's not all bad.

Suspension and handling are more important to me than power, so I put a fair amount of work into tuning it to my preference. I took a chance on the H&R adjustable coilovers as they were literally just released for sale a couple of weeks ago, and reviews are non-existent. Given H&R's tendency more towards the performance end of the spectrum of coilovers – which is what I'm looking for – I don't think I can go too wrong here. That said, I have drawn up some plans for a shock dyno that I can build for a couple of hundred bucks, so I may do some testing and re-valve the dampers to my preference. Proper damping requires spring rates to match your compression/rebound curves, so I chose H&R also because of their large variety of springs available, and should I re-valve the dampers, I can swap different springs in to match the new compression/rebound curves.

H&R Stainless Adjustable dampers:

I plan to keep this car as my daily for a few years, then get another daily (twin-turbo B7 RS4 sounds good to me ) and strip this car, and turn it into a track car (road course). I'm confident that I can get it down to 2800lbs plus cage – with 500wHP and AWD, it should haul ***. I hope to hell Race City finds new land for next year!

) and strip this car, and turn it into a track car (road course). I'm confident that I can get it down to 2800lbs plus cage – with 500wHP and AWD, it should haul ***. I hope to hell Race City finds new land for next year!

I built the engine myself, and blueprinted as follows: bored/honed to spec, weight-matching, ring gapping, rod and main mic'ing, Plastigauging, rod and crank axial gauging, deck-level gauging, and compression-ratio calculation. I tried to get the machine work done to somewhat loose clearances, and it paid off – I'm running about 75-80% of the way toward the loose end of manufacturer specifications all around, which is exactly what I wanted. I did not have the rotating assembly balanced, but I did weight-match each piston/rod/wrist-pin/ring/bearing assembly to >0.5 gram from lightest to heaviest.

I calculated all bearing clearances by subtracting the journal diameter from the sum of the bearing thickness and bore of the rod/main; which, yields the clearance. Plastigauging is a less accurate technique, but in this case I did it as a safety-check, and the numbers were consistent with my measurements.

Essential tools for engine blueprinting (not pictured is an inside micrometer).

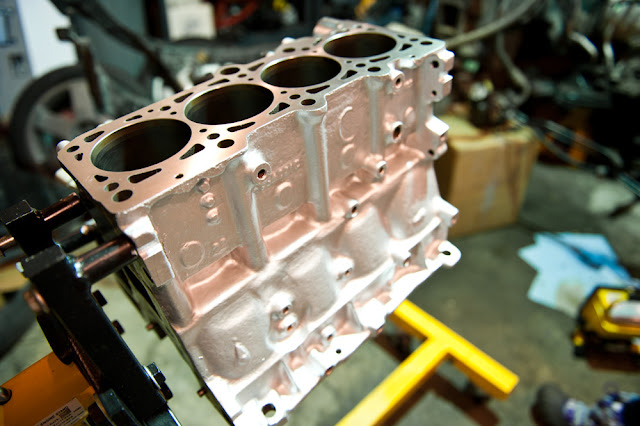

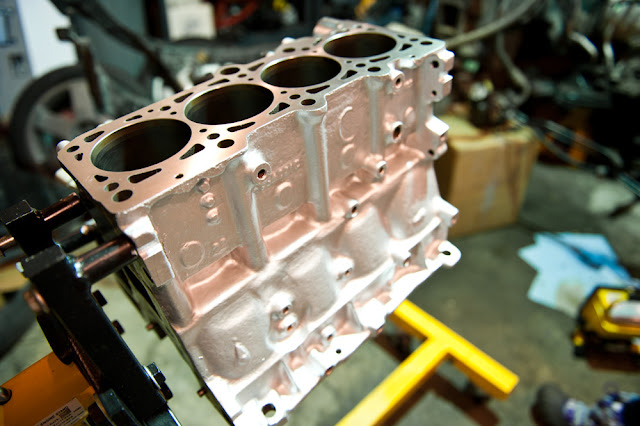

Block decked, cleaned, painted and ready to go:

The AEB head (found only on '97-'99 Passats and A4s) flows ~30% more than all other 1.8T heads; which, is a big deal since VAG heads flow like crap compared to something like a Honda.

Ready for assembly:

I've never used anything but OEM bearings before, and let me tell you: I'm a convert to coated race bearings. They are much more uniform, and obviously constructed of higher-quality materials, than basic bearings. I've been shocked at some of the crap quality I've seen in OEM bearings.

Hand-held macro FTW!

I'm also a convert to high-quality fasteners! The ARP bolts are a thing of beauty next to a standard bolt – there's just no contest. I have much more 'faith' in fasteners of this grade.

I didn't snap any pics, but I also measured the volume of the combustion chamber and piston dish, and deck height, in order to calculate my true compression ratio. This link explains the math better than I can in any less than 4 paragraphs: Compression Ratio. I CC'ed the piston dish and combustion chamber by sealing the rings and valves with grease, then sealing them off with plexiglass and dispensing a measured volume of oil into the enclosure. My numbers were comparable to other people who have done the same on the 20V, and my resulting compression ratio comes out to be 9.9x:1. I'm very happy with this figure, as it's a considerable increase over stock – something which will yield better off-boost response, increased fuel economy, and higher ultimate power numbers. Cylinder pressure = power

ARP Main studs in; lower bearings assembly lubed and waiting for the crank:

Plastigauging - in this case the main clearance specs are 0.0008" - 0.0024". I'm right at 0.002", or 75% of the way to the 'loose' limits - perfect for a high-performance engine!

Mains in - pistons next!

My assistant broke her arm a week ago

The rings didn't need much gapping, but I used a ring grinder to get them into my specs, and clocked them to 180°.

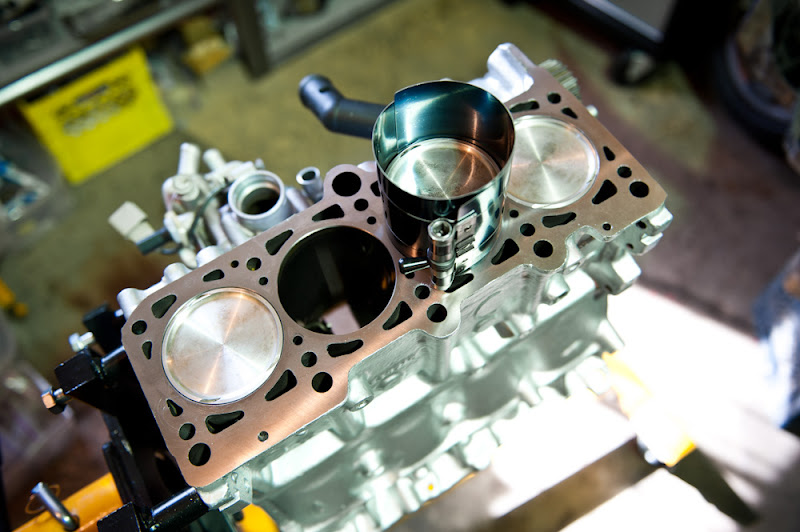

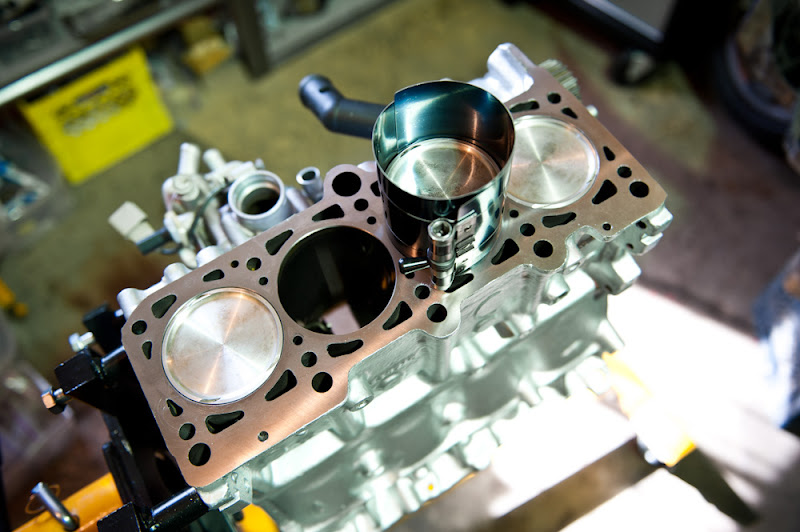

Block done and ready to bolt the head on:

Ready for timing gear and to go back in the car:

Treadstone TR8 – I have Vibrant 2.5” aluminum piping and will be welding a custom setup.

For some odd reason, VAG made the '02 TT a narrowband 02-sensor vehicle; so, I bought a Golf ECU so that I can convert to wideband 02. I had to rewire the pinouts on the ECU harness, but it was not much work for benefits it will yield, e.g., smoother idle, additional power via tune, etc. I also threw in an AEM UEGO while I was at it. I'm trying to keep the gauges in my interior to a minimum, but I feel that a boost, oil pressure, and A/F gauge are requirements at this level. I'm going to see if I can work an EGT in cleanly as well.

Given that real estate is at a premium in the TT, I used my OEM washer-fluid bottle for a methanol reservoir (-40°C washer fluid is ~50% methanol, which is a perfect blend if there's no harsh additives). This is also provides me with a built-in low-level warning so I'm not running a 104-octane map on pump with no meth!

I love my Wilwood brakes! Fixed calipers are not for everyone as they require pretty much annual maintenance, but their response and performance is significantly better than floating calipers.

I put in new hubs and bearings, and finally did a front stud conversion. I've been running studs in the rear for a while, and am ecstatic to not have to deal VAG wheel bolts any more.

I just got the turbo/manifold/injectors today, I have some more parts coming on Tuesday, and I still have to weld up the IC piping, so I should have it all running by Friday. C'moooooon Sunshine! :beer2:

450wHP on 94 octane @ <=28PSI; no N2O

22PSI by 3500RPM

11.xx 1/4 mile

>30MPG

Daily driver that can kick the crap outta SK Winters (AWD + Studded Winters + balanced chassis = love)

Engine:

2.0L displacement, 10:1 compression

Bored to 82.5mm – Wossner pistons (I wanted 83mm, but it would have been a 6-week wait for pistons!)

Stroked to 92.8mm - AEG crank

AEB head – Supertech Inconel valves

ARP Main, rod, and head fasteners

Calico coated ACL race bearings - rods and mains

GT3071R turbo, .63 AR

Treadstone TR8 with custom aluminum piping

3” Stainless turbo-back

Eurodyne Maestro

Wide-band O2 conversion

Water/meth injection

Lucas 830cc injectors, Walbro inline pump

Suspension/Chassis:

H&R SS-adustable coilovers

19mm rear anti-sway

Adjustable rear control arms

Defcon bushings, spherical bearings, poly bushings/mounts

~225lbs weight reduction

Wheels/Tires/Brakes:

17” OZ Ultraleggera

Bridgestone RE-01R

Wilwood Superlite Calipers

330mm two-piece, aluminum-hat rotors

ATE Super Blue

This car is my daily driver so I'm basing the build around drivability. The engine/suspension/brakes can easily handle another 100+wHP with just a different turbo (GT35+), but I'm trying to keep it moderate. Spool and power-band are very important to me, hence my choice of a turbo that some would find to be under-sized considering the build. I'm leaving a couple of mods on the table – cams and an SEM intake manifold – just to give me something to quell inevitable future mod-itis. I should have no problem with 400wHP as-is, then the cams and manifold will easily pull another 50+wHP, but my turbo will be maxed out at that point. Depending on how I feel about the drivability, I might go to a GT3076R and push for 500wHP. My only regret is that I didn't do the extra work and go to 2.2L of displacement; although, doing so does put the rod ratio and angles at fairly undesirable levels for a daily driver, so it's not all bad.

Suspension and handling are more important to me than power, so I put a fair amount of work into tuning it to my preference. I took a chance on the H&R adjustable coilovers as they were literally just released for sale a couple of weeks ago, and reviews are non-existent. Given H&R's tendency more towards the performance end of the spectrum of coilovers – which is what I'm looking for – I don't think I can go too wrong here. That said, I have drawn up some plans for a shock dyno that I can build for a couple of hundred bucks, so I may do some testing and re-valve the dampers to my preference. Proper damping requires spring rates to match your compression/rebound curves, so I chose H&R also because of their large variety of springs available, and should I re-valve the dampers, I can swap different springs in to match the new compression/rebound curves.

H&R Stainless Adjustable dampers:

I plan to keep this car as my daily for a few years, then get another daily (twin-turbo B7 RS4 sounds good to me

I built the engine myself, and blueprinted as follows: bored/honed to spec, weight-matching, ring gapping, rod and main mic'ing, Plastigauging, rod and crank axial gauging, deck-level gauging, and compression-ratio calculation. I tried to get the machine work done to somewhat loose clearances, and it paid off – I'm running about 75-80% of the way toward the loose end of manufacturer specifications all around, which is exactly what I wanted. I did not have the rotating assembly balanced, but I did weight-match each piston/rod/wrist-pin/ring/bearing assembly to >0.5 gram from lightest to heaviest.

I calculated all bearing clearances by subtracting the journal diameter from the sum of the bearing thickness and bore of the rod/main; which, yields the clearance. Plastigauging is a less accurate technique, but in this case I did it as a safety-check, and the numbers were consistent with my measurements.

Essential tools for engine blueprinting (not pictured is an inside micrometer).

Block decked, cleaned, painted and ready to go:

The AEB head (found only on '97-'99 Passats and A4s) flows ~30% more than all other 1.8T heads; which, is a big deal since VAG heads flow like crap compared to something like a Honda.

Ready for assembly:

I've never used anything but OEM bearings before, and let me tell you: I'm a convert to coated race bearings. They are much more uniform, and obviously constructed of higher-quality materials, than basic bearings. I've been shocked at some of the crap quality I've seen in OEM bearings.

Hand-held macro FTW!

I'm also a convert to high-quality fasteners! The ARP bolts are a thing of beauty next to a standard bolt – there's just no contest. I have much more 'faith' in fasteners of this grade.

I didn't snap any pics, but I also measured the volume of the combustion chamber and piston dish, and deck height, in order to calculate my true compression ratio. This link explains the math better than I can in any less than 4 paragraphs: Compression Ratio. I CC'ed the piston dish and combustion chamber by sealing the rings and valves with grease, then sealing them off with plexiglass and dispensing a measured volume of oil into the enclosure. My numbers were comparable to other people who have done the same on the 20V, and my resulting compression ratio comes out to be 9.9x:1. I'm very happy with this figure, as it's a considerable increase over stock – something which will yield better off-boost response, increased fuel economy, and higher ultimate power numbers. Cylinder pressure = power

ARP Main studs in; lower bearings assembly lubed and waiting for the crank:

Plastigauging - in this case the main clearance specs are 0.0008" - 0.0024". I'm right at 0.002", or 75% of the way to the 'loose' limits - perfect for a high-performance engine!

Mains in - pistons next!

My assistant broke her arm a week ago

The rings didn't need much gapping, but I used a ring grinder to get them into my specs, and clocked them to 180°.

Block done and ready to bolt the head on:

Ready for timing gear and to go back in the car:

Treadstone TR8 – I have Vibrant 2.5” aluminum piping and will be welding a custom setup.

For some odd reason, VAG made the '02 TT a narrowband 02-sensor vehicle; so, I bought a Golf ECU so that I can convert to wideband 02. I had to rewire the pinouts on the ECU harness, but it was not much work for benefits it will yield, e.g., smoother idle, additional power via tune, etc. I also threw in an AEM UEGO while I was at it. I'm trying to keep the gauges in my interior to a minimum, but I feel that a boost, oil pressure, and A/F gauge are requirements at this level. I'm going to see if I can work an EGT in cleanly as well.

Given that real estate is at a premium in the TT, I used my OEM washer-fluid bottle for a methanol reservoir (-40°C washer fluid is ~50% methanol, which is a perfect blend if there's no harsh additives). This is also provides me with a built-in low-level warning so I'm not running a 104-octane map on pump with no meth!

I love my Wilwood brakes! Fixed calipers are not for everyone as they require pretty much annual maintenance, but their response and performance is significantly better than floating calipers.

I put in new hubs and bearings, and finally did a front stud conversion. I've been running studs in the rear for a while, and am ecstatic to not have to deal VAG wheel bolts any more.

I just got the turbo/manifold/injectors today, I have some more parts coming on Tuesday, and I still have to weld up the IC piping, so I should have it all running by Friday. C'moooooon Sunshine! :beer2:

#4

Obligatory turbo-n'-beer shot:

Got the 3" 304SS downpipe (wish I could TIG like this )

)

The turbo turbine and manifold are both coated, and the downpipe is getting wrapped. I'll be putting a turbo blanket on before the Summer heat gets here, as well. I'm hoping to get it running by Monday, barring and problems or waiting for parts.

Got the 3" 304SS downpipe (wish I could TIG like this

The turbo turbine and manifold are both coated, and the downpipe is getting wrapped. I'll be putting a turbo blanket on before the Summer heat gets here, as well. I'm hoping to get it running by Monday, barring and problems or waiting for parts.

#5

Hi there,

I am in awe.

This is awesome!

I am having a Frankenturbo F23 and 42 Draft Design 3" turbo back installed in my 2001 225TT.

At the end of this month I should be good to go.

My build pales in comparison.

kudos

Randy.

I am in awe.

This is awesome!

I am having a Frankenturbo F23 and 42 Draft Design 3" turbo back installed in my 2001 225TT.

At the end of this month I should be good to go.

My build pales in comparison.

kudos

Randy.

#7

I primed the engine, then ran a couple of heat cycles, changed the oil/filter, and took it out for some driving. The tune is a little lumpy down low, so I have to work on that, but it's running pretty well otherwise. All the work at making this car drivable has paid off - from the little boosting I did it spools very quickly, and the off-boost response is extremely good. I really think I could have went with a larger turbo without turning it into a dyno queen. Maybe I'll move to a HTA3076R and go for 500wHP once I get bored

I'll post some more pics when I've got time, and get some shots of the car when I get it cleaned up. Next up: 'bout 12-18 hours of detailing, and a new bleeder valve on the clutch slave cylinder since it's weeping.

Crazybohunk, the F23 and turbo-back should make for a great daily driver! Get some good tires and suspension and you're set.

I'll post some more pics when I've got time, and get some shots of the car when I get it cleaned up. Next up: 'bout 12-18 hours of detailing, and a new bleeder valve on the clutch slave cylinder since it's weeping.

Crazybohunk, the F23 and turbo-back should make for a great daily driver! Get some good tires and suspension and you're set.

#10

Sorry for the lack of updates - I've been busy with my new part-time job: pulling my transmission!  Here's what I've been doing:

Here's what I've been doing:

I had a small oil leak that was coming from the bottom of the tranny - I looked everywhere, hoping that it was anything but the rear main. When I couldn't find anything else, I got a new rear main and pulling the tranny...turns out the leak was from the one place that was impossible to see with the transmission in place: the very back of the turbo oil drain, and running down and dripping into the bellhousing. :thumbd:

So, I drove it for a while, then started have some weird shuddering issues, which turned out to be a very small amount of gear oil weeping out of the transmission input-shaft seal that was being centrifuged out onto the clutch disc. I'm harbouring a lot of hate for this POS right now :

:

It was such a small amount that it couldn't be seen without removing the clutch slave, which I didn't do the three times that I've had my tranny out in the last couple months Soooooo, out comes the tranny again, and I decided to upgrade to a 6-puck disc while it was out again:

Soooooo, out comes the tranny again, and I decided to upgrade to a 6-puck disc while it was out again:

MMMmmmMMM, metallic-y goodness:

The clutch is surprisingly easy to daily drive - it's surely pretty grabby, but I think the people that complain about race-y clutches just can't drive stick all that well. My heel-toe downshifts aren't butter smooth now, but I'm sure I'll adapt. It was worth it to ensure that I won't have to pull that damn tranny again for a long time

Then I had a coolant flange spring a leak (thanks for making it out of non-heat resistant plastic, VAG), and my coil-packs started failing, so needed a new set. Once again, thanks to Cam at CWS for letting me come by pretty much twice a week to pick up last minute parts :beer2: I put in some 2.0T coilpacks, which run a higher voltage so I should be getting a cleaner burn, and hence making more power and better fuel economy. I also rebuilt the Wilwoods, and got new front rotor rings and hats since the old ones were getting rather worn.

Anyways, the car is making awesome power now, so I think I might pick up Integrated Engineering's new cams, and start tweaking my tune. I've seen a couple of 1.8Ts run <11.5 at ~130MPH on this turbo now, so I'm excited to get it dialed in. I might enjoy it this year, and move up to a HTA3076 next Spring. Other than that, I'll focus on suspension/steering mods to get it handling as sharply as I can - I'm going to try some custom Delrin bushings on the control arms to get the steering even more tight and responsive.

Just a quick snapshot in the driveway after ~20 hours of polishing, but I'll set up a proper photo-shoot sometime soon. There's not even any wax/sealant on it yet - that's just raw paint!

I forgot to note that I put in an Evo X diverter valve to replace my aftermarket one. With the crush mod done to it, it's much quicker to respond that any valve I've ever used. It's huge and ugly, and I have to run adapters to use it, but it just outperforms, by a considerable margin, anything I've ever ran. I'll snap some pics of the engine bay once I get everything dialed in and route the plumbing nicely.

Here's what I've been doing:

Here's what I've been doing:I had a small oil leak that was coming from the bottom of the tranny - I looked everywhere, hoping that it was anything but the rear main. When I couldn't find anything else, I got a new rear main and pulling the tranny...turns out the leak was from the one place that was impossible to see with the transmission in place: the very back of the turbo oil drain, and running down and dripping into the bellhousing. :thumbd:

So, I drove it for a while, then started have some weird shuddering issues, which turned out to be a very small amount of gear oil weeping out of the transmission input-shaft seal that was being centrifuged out onto the clutch disc. I'm harbouring a lot of hate for this POS right now

It was such a small amount that it couldn't be seen without removing the clutch slave, which I didn't do the three times that I've had my tranny out in the last couple months

Soooooo, out comes the tranny again, and I decided to upgrade to a 6-puck disc while it was out again:

Soooooo, out comes the tranny again, and I decided to upgrade to a 6-puck disc while it was out again:

MMMmmmMMM, metallic-y goodness:

The clutch is surprisingly easy to daily drive - it's surely pretty grabby, but I think the people that complain about race-y clutches just can't drive stick all that well. My heel-toe downshifts aren't butter smooth now, but I'm sure I'll adapt. It was worth it to ensure that I won't have to pull that damn tranny again for a long time

Then I had a coolant flange spring a leak (thanks for making it out of non-heat resistant plastic, VAG), and my coil-packs started failing, so needed a new set. Once again, thanks to Cam at CWS for letting me come by pretty much twice a week to pick up last minute parts :beer2: I put in some 2.0T coilpacks, which run a higher voltage so I should be getting a cleaner burn, and hence making more power and better fuel economy. I also rebuilt the Wilwoods, and got new front rotor rings and hats since the old ones were getting rather worn.

Anyways, the car is making awesome power now, so I think I might pick up Integrated Engineering's new cams, and start tweaking my tune. I've seen a couple of 1.8Ts run <11.5 at ~130MPH on this turbo now, so I'm excited to get it dialed in. I might enjoy it this year, and move up to a HTA3076 next Spring. Other than that, I'll focus on suspension/steering mods to get it handling as sharply as I can - I'm going to try some custom Delrin bushings on the control arms to get the steering even more tight and responsive.

Just a quick snapshot in the driveway after ~20 hours of polishing, but I'll set up a proper photo-shoot sometime soon. There's not even any wax/sealant on it yet - that's just raw paint!

I forgot to note that I put in an Evo X diverter valve to replace my aftermarket one. With the crush mod done to it, it's much quicker to respond that any valve I've ever used. It's huge and ugly, and I have to run adapters to use it, but it just outperforms, by a considerable margin, anything I've ever ran. I'll snap some pics of the engine bay once I get everything dialed in and route the plumbing nicely.