C5 A6, 3L BAMFT Build Thread

#1

This build has been in planning for the past couple of years, I am not great at remembering to take pics, but I sure will try.

I need to put a big thanks out to my friend Brenden for allowing me to use his garage space for the tear down and early stages of fabrication and Tyler L for allowing me to bounce crazy ideas off him for the last year and a half.

Chris @ Unobtanium welding deserves recognition as the one who is helping me to realize my vision, he will be the brains and the skill behind this build. Without Chris' belief and desire to make this project a reality, it would never be happening.

Tuning to be done by Mr Piggy, hot on the heals of their Mafless project IX car, space being limited this car will run mafless

The build

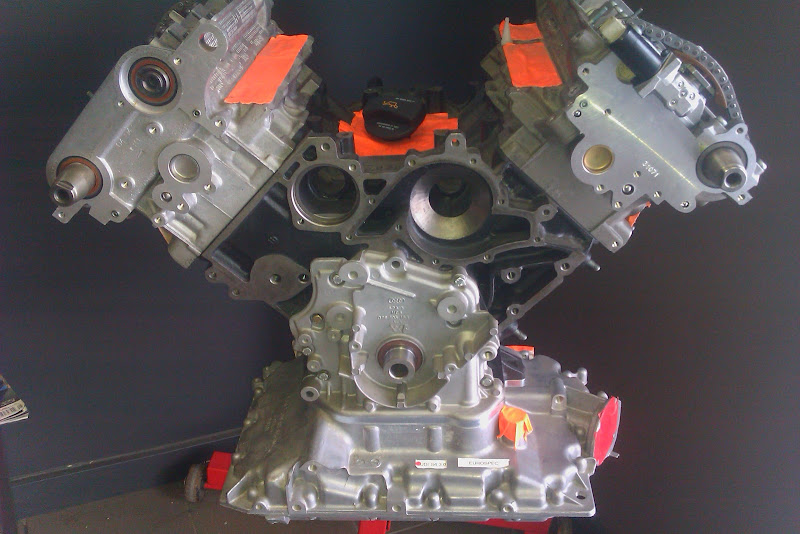

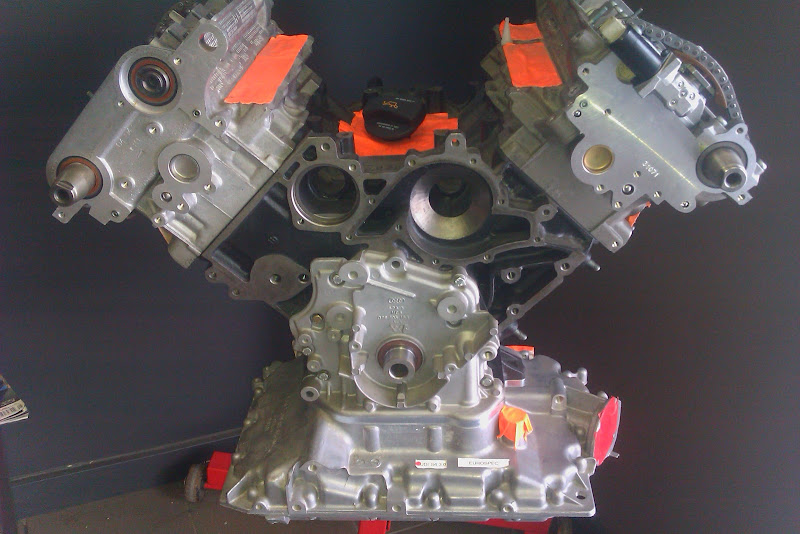

Motor, I was in the process of building a 3L, a local shop had a fully built, guaranteed to 1200hp+ motor , so I sold my block/crank/piston/rods and picked up the motor that was ready to roll. It has all sorts of things that I wanted to do, but cost was prohibitive. It is a Eurospec full built 3L, JE 8.5:1 compression, knife edged forged crank, deck cooling, crank girdle, 2.8 NA heads, I picked up a set of Rosten valve springs and Ti retainers, to go with Supertech valves. Here is a pic of it in the shop before I picked it up

Turbo, I spent almost 2 years agonizing over which turbo to go with, I did countless math calculations, I wanted to make sure that I could spool the turbo before 7K. Anyways, as I watched the addition of the Garrett GTX turbos, and countless other brands, I kept coming back to the turbo I originally specced 2 years ago, of course Bullseye had undergone some improvements to their lineup as well. I ended up getting a B383, it is billet wheel, 83mm inducer, 119mm exducer on the comp side, v-band discharge. Turbine side is an 87mm wheel, turbine housing is stainless v-band in/out, no comp maps have been released, but it should flow in the neighborhood of 130lbs/min, enough to support 1200awhp

To go with these goodies I have a rather large FMIC, it is not my first choice to run a FMIC, but this year with time permitted it will do the trick. This core should easily flow enough to keep my charge cool, my only worry is pressure drop. Next year we will set to work on a proper Air/Water IC setup. Fueling will be handled by a Magnafuel in-line 750 MP-4303 fuel pump(still waiting for delivery, after great deliberation on which pump to buy) Injector Dynamics ID1000 at base pressure of 70psi should be sufficient this year, might have to move these to the ID1600 next year. Fuel rails are -10 an, building for the possibility of E85 if Canada ever gets some. Fuel regulator and filters are Magnafuel, still waiting on delivery. All lines will be run in Earl's plumbing and AN fittings

I pulled the old stage 3 setup last week, started cleaning up the engine bay, the turbo is mounting where the air box had been located. I cut out the secondary firewall and cut the battery tray back to the mount tabs for the steering rack. It gives us a solid 5" extra space in back of the motor. I still have a bunch of clean up to do but it is coming along. I removed the wiring harness and have started rebuilding it, the harness and the PS hardline should be all that we need to change behind the motor.

I need to put a big thanks out to my friend Brenden for allowing me to use his garage space for the tear down and early stages of fabrication and Tyler L for allowing me to bounce crazy ideas off him for the last year and a half.

Chris @ Unobtanium welding deserves recognition as the one who is helping me to realize my vision, he will be the brains and the skill behind this build. Without Chris' belief and desire to make this project a reality, it would never be happening.

Tuning to be done by Mr Piggy, hot on the heals of their Mafless project IX car, space being limited this car will run mafless

The build

Motor, I was in the process of building a 3L, a local shop had a fully built, guaranteed to 1200hp+ motor , so I sold my block/crank/piston/rods and picked up the motor that was ready to roll. It has all sorts of things that I wanted to do, but cost was prohibitive. It is a Eurospec full built 3L, JE 8.5:1 compression, knife edged forged crank, deck cooling, crank girdle, 2.8 NA heads, I picked up a set of Rosten valve springs and Ti retainers, to go with Supertech valves. Here is a pic of it in the shop before I picked it up

Turbo, I spent almost 2 years agonizing over which turbo to go with, I did countless math calculations, I wanted to make sure that I could spool the turbo before 7K. Anyways, as I watched the addition of the Garrett GTX turbos, and countless other brands, I kept coming back to the turbo I originally specced 2 years ago, of course Bullseye had undergone some improvements to their lineup as well. I ended up getting a B383, it is billet wheel, 83mm inducer, 119mm exducer on the comp side, v-band discharge. Turbine side is an 87mm wheel, turbine housing is stainless v-band in/out, no comp maps have been released, but it should flow in the neighborhood of 130lbs/min, enough to support 1200awhp

To go with these goodies I have a rather large FMIC, it is not my first choice to run a FMIC, but this year with time permitted it will do the trick. This core should easily flow enough to keep my charge cool, my only worry is pressure drop. Next year we will set to work on a proper Air/Water IC setup. Fueling will be handled by a Magnafuel in-line 750 MP-4303 fuel pump(still waiting for delivery, after great deliberation on which pump to buy) Injector Dynamics ID1000 at base pressure of 70psi should be sufficient this year, might have to move these to the ID1600 next year. Fuel rails are -10 an, building for the possibility of E85 if Canada ever gets some. Fuel regulator and filters are Magnafuel, still waiting on delivery. All lines will be run in Earl's plumbing and AN fittings

I pulled the old stage 3 setup last week, started cleaning up the engine bay, the turbo is mounting where the air box had been located. I cut out the secondary firewall and cut the battery tray back to the mount tabs for the steering rack. It gives us a solid 5" extra space in back of the motor. I still have a bunch of clean up to do but it is coming along. I removed the wiring harness and have started rebuilding it, the harness and the PS hardline should be all that we need to change behind the motor.

#4

Still in the works, next year we are doing a custom all steel widebody, so I will most likely stick with my H&R/Bilstein setup this year, looking for some wider wheels right now to get me by until then

#5

Besides I am running short on cash coming near the end of this build, I want to be able to focus all the funds that are required towards getting the motor and turbo sorted

#6

I know the fellas at VAST and have been there a few times. If I can help getting parts or shipping / receiving items for you let me know? I am closer and a drive to VAST is less than 2 hours.

#8

Guess that means I'll have to source out other means of lowering mine huh

Leonard